Vom Sensor über Daten zum Mehrwert

Für viele Konstrukteure und Produktentwickler ist das Thema Industrie 4.0 längst Teil der Realität, die eine Auseinandersetzung im täglichen Alltag erfordert. Doch was konkret verbirgt sich eigentlich hinter den „Daten“ der „cyberphysischen Systeme“ und wann liefern diese tatsächlich einen Mehrwert?

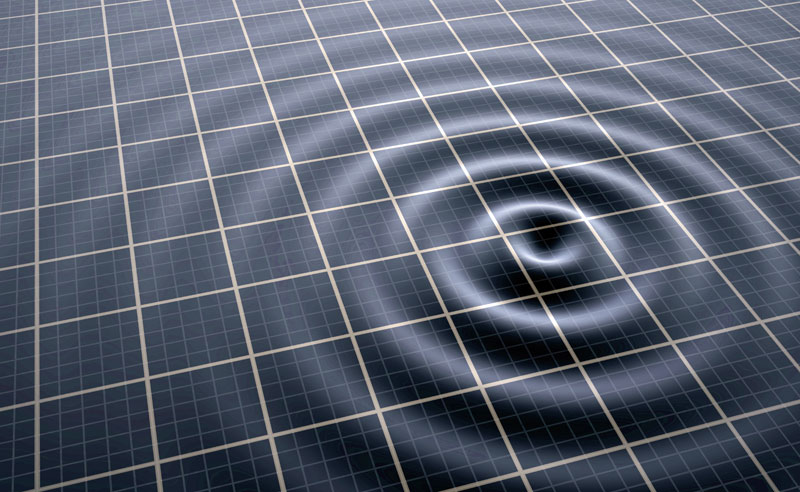

What remains at times rather vague, in superficial considerations regarding Industry 4.0, needs to be defined and analyzed more precisely here: What do measurement data, or generally speaking physical test and measurement, mean for system designers and product developers? Data are representing, for example, the results of tests that capture the real world performance under realistic operating conditions, in order to match them with the design specifications and simulations. This often marks the transition from “digital prototype” to real prototype. Not only in the development environment, but also in the regular operation or production of standard products, the use of such test and measurement processes is a very important area of growth in the course of the “digital revolution“ associated with IoT and Industry 4.0. Keywords such as component test benches, durability testing, condition monitoring and predictive maintenance all hint at the broad range of relevant application fields.

The full white paper is available as a PDF in the column on the right under "Downloads".