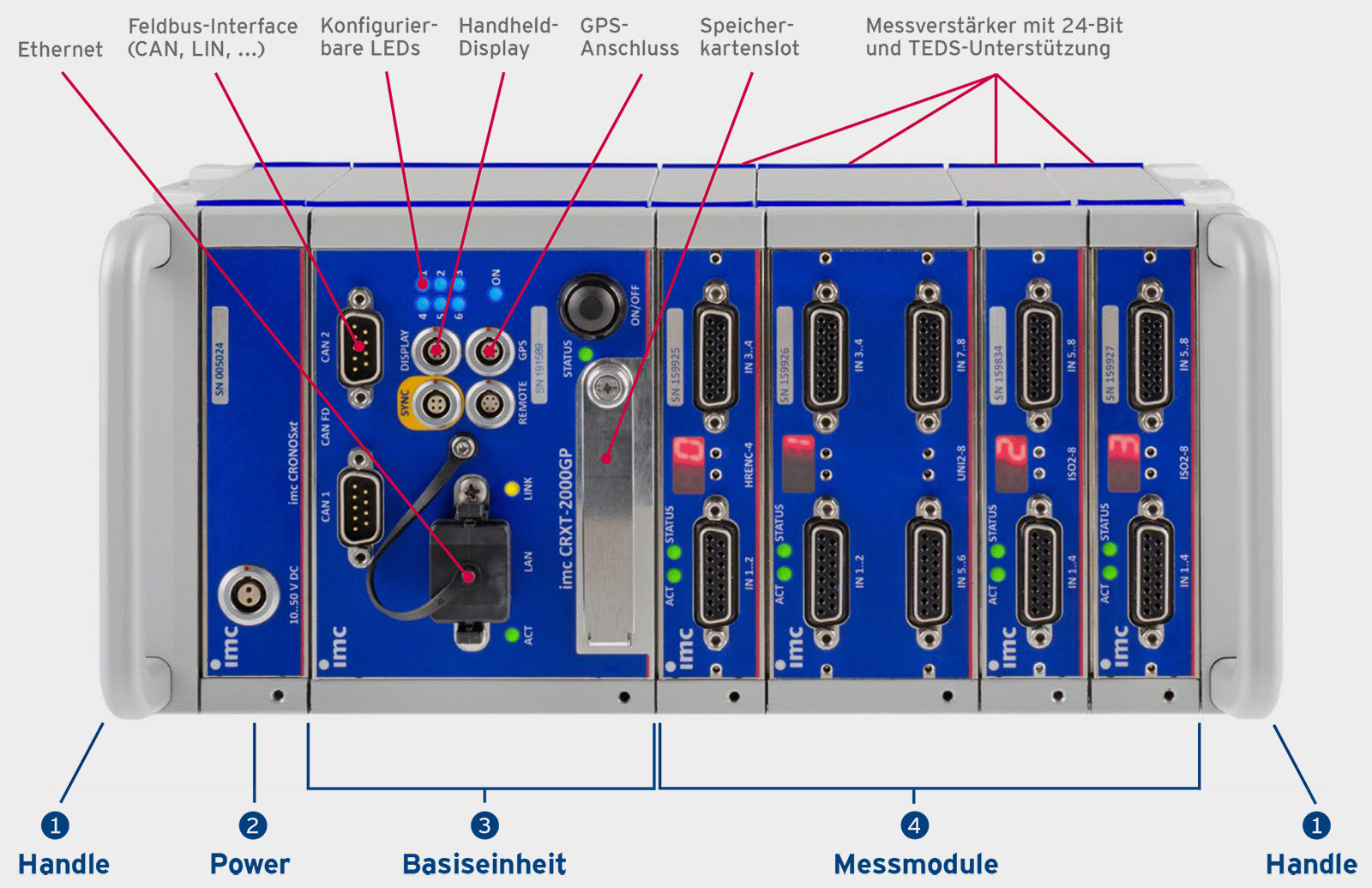

Robuste Datenerfassung mit Klick

Keine Kompromisse mehr: Mit imc CRONOS-XT bietet imc eine ultra-robuste Gerätetechnik in einer vollständig modularen Baukastenplattform. Datenerfassungseinheit und Messverstärker lassen sich komfortabel über einen Klickmechanismus werkzeugfrei und ohne Kabel zu einem Gesamtsystem verbinden. Mit Schutzart IP67 und MIL-STD810F ist das System gegen Dreck, Staub und Regen genauso geschützt wie vor starken Erschütterungen und Schock. Der robuste Datenlogger eignet sich daher ideal für mobile Messungen an Baumaschinen, Traktoren, Agrarmaschinen und Fahrzeugtests, die in rauen Umgebungen stattfinden.

Mehr Flexibilität im Messalltag

Heute steht eine 8-kanalige Vibrationsmessung an? Dann klicken Sie einfach das ICP-Messmodul an Ihre Basiseinheit und los geht's. Und morgen? Dank der modularen Baukastentechnologie, lässt sich imc CRONOS-XT in wenigen Minuten an jede anstehende Messaufgaben anpassen. Eine breite Palette an hochpräzisen Universal- und Spezial-Messverstärkern deckt nahezu alle Sensortypen ab wie Thermoelemente, RTD (PT100/1000), Spannungs- und Stromsignale, Beschleunigungs- und Schallsensoren (IEPE), Wegaufnehmer (LVDT) bis hin zu DMS als Voll-/Halb-/Viertelbrücken und entsprechende Brückensensoren wie Kraftmessdosen (Wägezellen). Die präzisen und rauscharmen Messverstärker digitalisieren mit 24 Bit und verfügen über hohe Bandbreite und Bereichsdynamik.

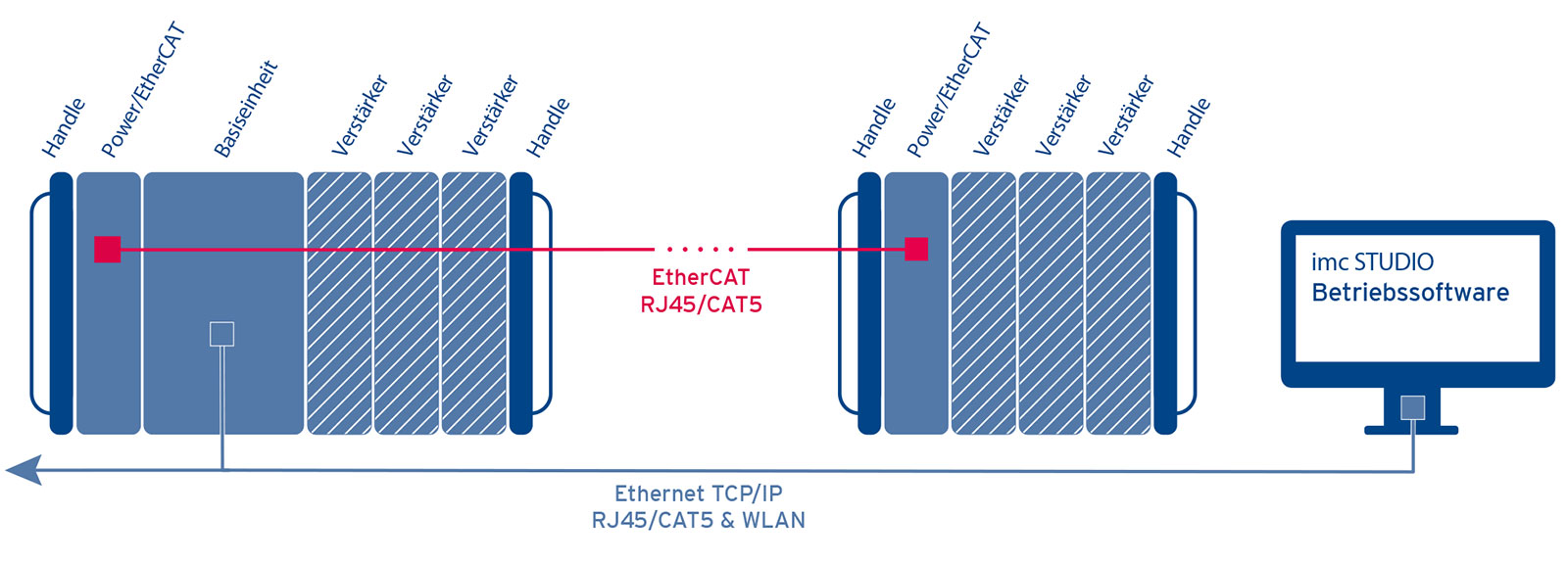

Räumlich verteilbar

Neben dem modularen Aufbau als zentrales DAQ-System, lässt sich imc CRONOS-XT auch räumlich verteilt einsetzen. So können Messverstärker nahe der Messstelle platziert werden, um die empfindlichen und teuren Messleitungen auf ein Minimum zu reduzieren. Die Vernetzung erfolgt dabei über den EtherCAT-basierten imc Systembus. Alle Daten laufen synchron in der Basiseinheit zusammen.

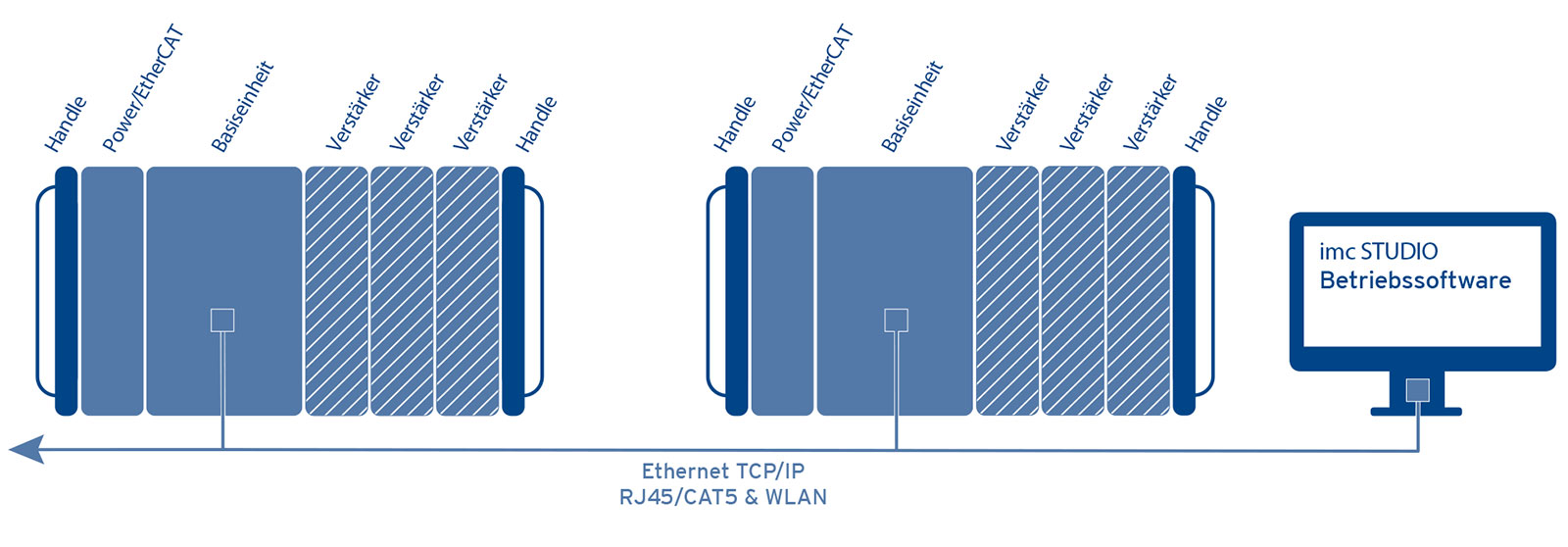

Vernetzbar mit weiteren Geräten

Für umfangreiche Messungen mit hunderten oder tausenden von Kanälen lassen sich mehrere imc CRONOS-XT und alle weiteren imc Messsysteme in einer Messung gemeinsam betreiben. Dazu werden die Geräte einfach über Ethernet vernetzt und via DCF77, IRIG-B, GPS oder PTP synchronisiert. Die Daten werden entweder autark in den Geräten gespeichert und/oder über Netzwerk-Streaming zu einem NAS oder PC transferiert.

Echtzeitanalysen im Gerät

Sorgen Sie für fertige Ergebnisse während der laufenden Messung. Mit der integrierten Rechenplattform imc Online FAMOS verrechnen und analysieren Sie Ihre Rohdaten in Echtzeit. Über einen komfortablen Assistenten erstellen Sie Ihren persönlichen Echtzeit-Analysator: einfach per Drag & Drop aus einer umfassenden Sammlung aus mathematischen und statischen Funktionen sowie fertigen Analysen wie z.B. FTT, Klassierung und Ordnungsanalyse. Damit ist es ganz ohne Programmierung möglich, eigene Auswertealgorithmen zu erstellen und Smart-Data-Analysen aufzusetzen.

Damit sind komprimierte und intuitiv erfassbare Resultate nicht nur direkt aus dem autarken Gerät verfügbar (ohne PC), sie können auch live auf einem imc Handheld Display dargestellt werden. So bekommen Sie noch während des Tests, etwa bei einer Erprobungsfahrt, ein direktes Feedback zum laufenden Versuch, worauf unmittelbar reagiert werden kann z.B. durch entsprechende Fahrmanöver.

Testmessung im harten Alltag

Baumaschinen und Landtechnik müssen einiges aushalten. Umso wichtiger ist es, bei deren Entwicklung, umfassende Funktions- und Stresstests durchzuführen. Mit imc CRONOS-XT haben Sie das ideale Werkzeug dazu. Universal-Messverstärker messen präzise alle an der Maschine installierten Sensoren inklusive DMS, IEPE/ICP, Weg, Kraft und Druck und führen Echtzeitanalysen aus, z.B. zur Rosetten-Berechnungen oder Spektralanalyse (FFT). Das robuste Gehäuse schützt die Messtechnik zuverlässig vor Staub, Wasser und Dreck.

Schall & Schwingung auf der Spur

Zum Schutz von Mensch und Umwelt, müssen Fahrzeuge und Maschinen zahlreiche Grenzwerte einhalten. Unter anderem in Bezug auf die Schallemission, aber auch in Bezug auf Vibrationen, die auf Mensch und Bauteile einwirken. Mit imc CRONOS-XT und der Software imc WAVE steht Anwendern ein umfassendes Komplett-Paket für Schall- und Schwingungsanalysen zur Verfügung: Von Geräuschuntersuchungen im Fahrversuch über Strukturanalysen am Prüfstand bis hin zu Schwingungsprüfungen im Feldeinsatz.

Erfassen von Lastkollektiven

Mit imc CRONOS-XT steht Testingenieuren das ideale System zum Erfassung von realen Lastprofilen auf der Straße zur Verfügung. Dank der hohen Schock- und Vibrationsfestigkeit nach MIL-STD-810F ist es in der Lage, auch unter extremen Bedingungen zuverlässig Testdaten aufzuzeichnen. Das Echtzeit-Betriebssystem sorgt für einen lückenlosen 24/7-Messbetrieb. Besonders hilfreich für wochenlange Testfahrten sind Funktionen wie Selbststart, Online-Klassierung, GPS-Tracking sowie Cloud-Anbindung für Messdatentransfer und Online-Monitoring.

Komfortable Messtechnik-Software

Egal ob Sie Ihr imc CRONOS-XT für eine schnelle mobile Messung im „black box“-Betrieb konfigurieren, ein Live-Monitoring für Hunderte von Kanälen im Prototypentest aufsetzen oder eine komplette Prüfstandsautomatisierung mit eigenem Bedienpanel erstellen möchten – mit imc STUDIO haben Sie die volle Kontrolle über Ihren kompletten Messprozess: Von der Kanalkonfiguration bis zum Report. imc STUDIO vereint Datenerfassung, Visualisierung, Analyse und Automatisierung.