Wheel Torque Transducer WTT-Dx

Acquire drive and output torques directly at the wheel

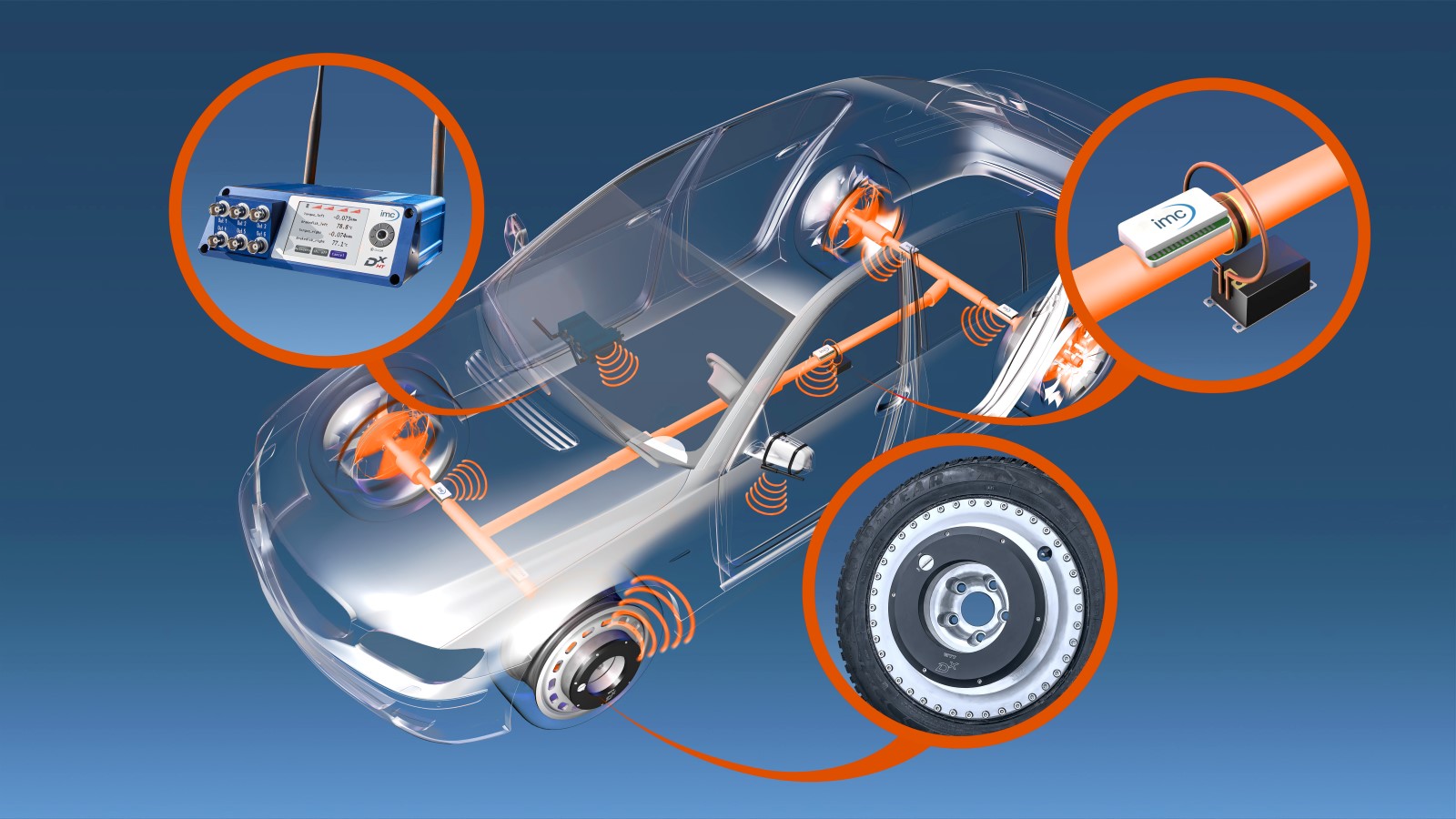

In automotive development, it is important to know the exact torques acting on the vehicle – especially under acceleration and braking maneuvers. With the WTT-Dx wheel torque transducer, a high-precision tool is available for making such measurements. The WTT detects the mechanical load directly where it is produced: the wheels that form the interface between the vehicle and the road.

Auf einen Blick:

- Präzise Messung von Antriebs- und Bremsmomenten direkt am Rad

- Kabellose Datenübertragung durch integrierte DX-Telemetrie

- Datenerfassung von bis zu vier Messrädern synchron mit einer DX-Empfangseinheit

- Austauschbarer Akku mit bis zu 80 h Laufzeit

- Arbeitstemperatur -10 °C bis +60 °C, optional mit Spezialakku -30 °C bis +60 °C

- Wasserdicht nach Schutzart IP67

- Nullabgleich und Start der Messung komfortabel per Software

- Analog- und CAN-Schnittstelle

Präzise und robust

Das Messrad WTT-DX erfasst mittels integrierter DMS-Sensoren hochaufgelöst das Drehmoment in Achsrichtung (My). Die volldifferenzielle Ausführung der DMS-Verstärker, einschließlich der Brückenspeisung, sorgt für ein Höchstmaß an Störunterdrückung.

Dank des cleveren Designs des Messkörpers liefert das Messrad auch bei dynamischen Fahrmanövern, die zu starker Erwärmung des Sensors führen, hoch präzise Messdaten. Die mechanische Stabilität des Messkörpers ist dabei auf die mehrfache Fahrzeuglebensdauer bei schweren SUVs ausgelegt.

Um Messungen bei Schnee, Eis und Tauwasser zu ermöglichen, wurden Messkörper, Stromversorgung und Elektronik in ein wasserdichtes (IP 67) Gehäuse integriert. Die im Sensor verbauten Spezialakkus ermöglichen Messungen bei einem Temperaturbereich von -30°C bis +60°C.

Kabellose Datenübertragung

Jedes WTT-Messrad ist mit einer digitalen Sendeeinheit des modularen Dx-Telemetriesystems ausgestattet. Die Messdaten von bis zu vier Drehmoment-Messrädern werden kabellos vom Rad an Empfangsantennen am Außenspiegel übertragen – dank Digitaltechnik störsicher und mit hoher Auflösung. Die in den Rädern integrierte Dx-Sendeeinheiten werden von der Empfangseinheit im Fahrzeug zentral angesteuert und getaktet. Diese hochgradig simultane Abtastung aller vier Räder ermöglicht es, schnelle Regelungsprozesse zwischen den Rädern mit hoher zeitlicher Präzision zu erfassen und zu validieren. Messdaten werden an der Empfangseinheit über CAN oder analog ausgegeben und sind damit leicht in bestehende Messsysteme zu integrieren.

Effizienzoptimierung am Antriebsstrang

Um Energieverbrauch und CO2-Ausstoß von Fahrzeugen zu senken, wird in der Automobilentwicklung die Effizienz von Antrieben untersucht und kontinuierlich verbessert. Bei Messungen am Antriebsstrang erfasst das WTT-Dx präzise das Drehmoment, welches direkt auf das Rad einwirkt. Weitere Messgrößen werden parallel an der Antriebswelle erfasst. Diese Daten werden benutzt, um Effizienz und Reibungsverluste entlang des Antriebsstrangs zu quantifizieren und zu modellieren.

Fahrdynamiktests bei Schnee, Eis, Regen

Im Wintertest sind Fahrzeug, Testingenieur und Messequipment nicht nur Schnee und Eis, sondern auch hohen Temperaturschwankungen und Schmelzwasser ausgesetzt. Das wasserfeste (IP67) und robuste Messrad WTT-Dx bewährt sich auch in dieser rauen Umgebung: Auswechselbare Spezialakkus ermöglichen den Einsatz des Systems bei Umgebungstemperaturen bis -30 °C. Der widerstandsfähige Sensorkörper ist für mechanische Belastungen bis ±6 kNm ausgelegt. Die einfache Montage und Bedienung ermöglichen einen schnellen und unkomplizierten Austausch von Komponenten.

Evaluierung von Antriebs- und Fahrassistenzsystemen

Moderne Allradfahrzeuge regeln die Verteilung von Antriebsmomenten auf die Räder innerhalb von Millisekunden, um Traktion, Spurtreue und Stabilität zu optimieren. Messräder, die zur Evaluierung von Fahrassistenzsystemen eingesetzt werden, müssen deshalb mit hoher zeitlicher Präzision Messwerte aufnehmen. Beim WTT-Dx werden alle vier Messräder synchron und in hoher zeitlicher Auflösung abgetastet. Die störsichere Übertragung (Diversity-Betrieb) minimiert Signalausfälle.

Passend für viele unterschiedliche Fahrzeugtypen

Mit dem Adaptersystem von imc können die Messräder mit minimalem Aufwand an unterschiedlichen Fahrzeugtypen montiert werden. Durch kurze Rüstzeiten und komfortable Softwarefunktionen, z.B. zum Nullabgleich, ist das System innerhalb kürzester Zeit messbereit. Drei Komponenten bilden zusammen das fahrzeugspezifische Rad.

- Felgenadapter:

Der Felgenadapter dient, wie bei einer herkömmlichen Felge, der Aufnahme des Pneus. Der Felgenadapter ist nicht direkt fahrzeugspezifisch, sondern reifenabhängig. Dadurch kann er auf vielen Fahrzeugen mit gleichen Reifengrößen verwendet werden. - Nabenadapter:

Der Nabenadapter dient der Anbindung des Messrades an das Fahrzeug. Er kann für unterschiedliche Fahrzeugtypen verwendet werden, solange Lochkreis und Einpresstiefe gleich sind. Mit wenigen Nabenadaptern lässt sich so eine gesamte Fahrzeugflotte abdecken. - Messkörper:

Der Messkörper (Sensor) verbindet den Nabenadapter und den Felgenadapter miteinander.

So entsteht nach einem Baukastenprinzip sowohl zeitsparend, raumsparend als auch kostengünstig mit wenigen Handgriffen ein auf das Fahrzeug angepasstes Messrad WTT-Dx.

In nur einer Stunde messbereit

Die Montage eines WTT-Messrads ist fast so einfach, wie ein Radwechsel. Vier Messräder sind in einer Stunde montiert. Dank komfortablen Softwarefunktionen, wie dem Nullabgleich, ist das System innerhalb kürzester Zeit messbereit.

WTT-DX Messrad

| Parameter | Wert | ||

|---|---|---|---|

| Messgröße | Drehmoment in Achsrichtung My | ||

| Signalübertragung | digital-telemetrisch | ||

| Messbereich | My = ±6000 Nm, optional, My = ±3000 Nm | ||

| Bandbreite | max. 1 kHz | ||

| Nichtlinearität des Messwertes | < 0,5 % | ||

| Hysterese | < 0,5 % | ||

| Übersprechen des Messwerts | < 0,5 % | ||

| Sensordurchmesser | 300 mm | ||

| Sensorgewicht | ca. 4,75 kg (inkl. Telemetrieeinheit) ca. 6,3 kg (mit Akku) | ||

| Material Sensorkörper | Aluminium | ||

| Mechanische Belastung | Betriebsfestigkeitsnachweis nach AK-LH-08 4.34 | ||

| Felgendurchmesser | ab 13" | ||

| Achsendurchmesser (mittels Nabenadapter) | max. 6" | ||

| Betriebstemperaturbereich | -10 °C bis +60 °C (Standard-Akku) -30 °C bis +60 °C (Spezial-Akku) | ||

| max. Fahrgeschwindigkeit | 250 km/h | ||

| max. Drehzahl | 2300 U/min | ||

| Stoßfestigkeit | 100 g | ||

| Schutzart | IP67 (wasserdicht) | ||

| Montage und Wuchten | Ja (freier Zugriff auf die Radschrauben) | ||

| Stromversorgung | Standard-Akku: bis zu 80 h Spezial-Akku: bis zu 40 h | ||

Telemetrie-Empfänger RCI

| Eigenschaften Telemetrie | Wert | ||

|---|---|---|---|

| Spannungsversorgung | 9 bis 36 V DC | ||

| Leistungsaufnahme | < 5 W | ||

| Frequenz | frei konfigurierbar im 868-MHz-Band (optional 2,4 GHz) | ||

| Synchronisierung | synchronisierte Abtastung von bis zu 4 Messräde | ||

| CAN-Ausgabe (Anschluss nach ISO 11898, galvanisch getrennt) | CAN 2.0b, Standard- & Extended-Identifier, frei programmierbar bis max. 1 MBaud | ||

| Analog-Ausgang | 6 x BNC-Buchse, (frei belegbar, Ausgangssignal max. ±10 V) | ||

| Ethernet | 10/100 Mbit | ||

| Autozero | fernsteuerbar | ||

| Temperaturbereich | -20 °C bis +65 °C | ||

| Abmessung | ca. 170 mm x 130 mm x 53 mm | ||

| Gewicht | 0,8 kg | ||

Control-Unit als zentraler Empfänger im Fahrzeug

Die Dx-Empfangseinheit RCI dient der Parametrierung und synchronen Signalerfassung von bis zu vier WTT-Messrädern. Die Ausgabe der Messdaten erfolgt über sechs frei belegbare Analogausgänge oder die integrierte CAN-Schnittstelle. Die Konfiguration aller Parameter wird komfortabel via Ethernet und Webbrowser oder direkt an der RCI durchgeführt und erlaubt Autozero und Shunt-Kalibrierung

auf Knopfdruck.

KFZ-Spiegelantennen zur Erfassung der Telemetriedaten

Durch die speziell entwickelten Empfangsantennen ist es möglich, sowohl im 868-MHz- als auch im 2,4-GHz-Bereich eine optimale Datenübertragung sicherzustellen. Die Außenspiegelantennen lassen sich mittels Gummizug schnell und einfach montieren und verfügen über 5 Meter Kabel.

Kalibrierung

imc kalibriert jedes Messrad an seinem eigens entwickelten Prüfstand. Jede Kraft- und Drehmomentrichtung wird separat vermessen. Wechselwirkungen (Crosstalk) zwischen den Messgrößen können so detektiert und kompensiert werden. Dies führt zu einer bisher unerreichten Präzision der Messwerte.

Weitere Messgrößen erfassen mit imc

Bei ganzheitlichen Tests von Fahrzeugen gilt es, viele verschiedene physikalische Größen zu erfassen. Neben den Radmomenten sind beispielsweise Beschleunigung, Kraft, Frequenzen oder Steuergeräteinformationen interessant. imc-Messgeräte sorgen für die synchrone Datenerfassung aller Signale - dabei lässt sich das Messrad WTT-Dx direkt einbinden. Anschließend bietet die imc-Software vielfältige Möglichkeiten zur Messdaten-Analyse, Visualisierung und Weiterverarbeitung.