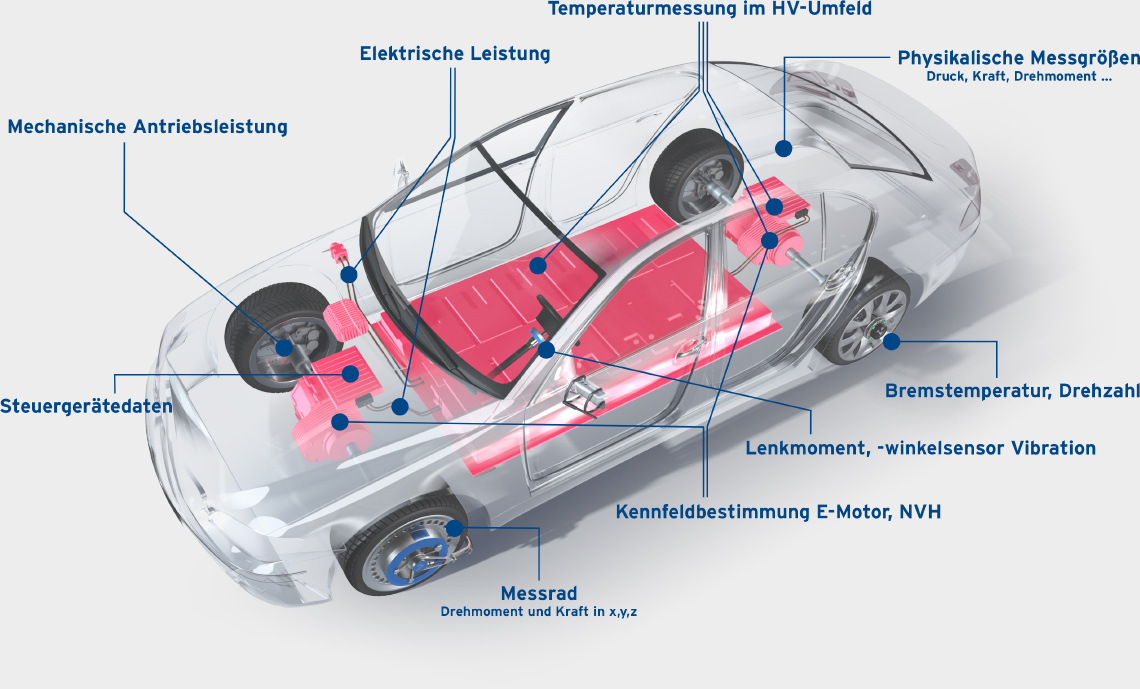

Wie sehen die Elektrofahrzeuge der Zukunft aus? Wie lässt sich der elektrische Antriebsstrang optimieren? Sind leistungsstärkere Batterien und Schnellladekonzepte der Schlüssel für die Weiterentwicklung der Elektromobilität? Schließlich beeinflusst die Batterie die Reichweite der Fahrstrecke und die Fahrzeugkosten entscheidend. Wie lässt sich das Gewicht von Fahrzeugkomponenten optimieren? Antworten auf diese Fragen kann es nur durch Tests und Messungen in der Entwicklung von elektrisch betriebenen Fahrzeugen geben. imc bietet die passenden Messlösungen dazu.

Innovative Lösungen für Test & Validierung von Hybrid- und Elektrofahrzeugen

Mit Hochvolt-Messmodulen, Hochisolation von Modulen im kV-Bereich, Strommesstechnik, Prüfständen, mobilen Datenerfassungssystemen und Datenanalyse-Software bietet imc ein breites Portfolio zur Lösung von Messaufgaben im Bereich der Elektromobilität. Ob beim Messen an Elektromotoren, Batterien, Brennstoffzellen oder Steckverbindern und Ladesäulen - profitieren Sie von unserer Expertise und erfahren Sie mehr über hochspannende Messtechnik-Lösungen von imc.

Temperaturmessung im HV-Umfeld (Thermoelement, PT-Sensoren, FBG-Faseroptik)

Spannungsmessung im HV-Umfeld (Batteriezellen, HV-Batterien, Zwischenkreis)

Strommessung im HV-Umfeld (Wandler, Zangen, Sensorversorgung)

Wirkungsgrad bestimmen / Leistungsanalyse (elektrisch und mechanisch)

Elektromotoren testen (Antriebsmaschine, Kleinmotoren)

Bordnetz-Konformität prüfen (Zertifizierungsmessung für LV124 etc.)

Weitbereichsstrommessung (ECUs, Komponenten)

NVH-Messung (Karosserie, Fahrwerk, Antriebsstrang)

Fahrdynamik prüfen (Messräder für hochdynamische Elektrofahrzeuge)

Temperaturmessung im HV-Umfeld

Bei der Entwicklung von Hybrid- und Elektrofahrzeugen werden an verschiedensten Komponenten Temperaturmessungen durchgeführt: von der Batterie über Steckverbinder und Leistungselektronik bis hin zum Elektromotor. Viele der Messstellen liegen auf hohem Potential und müssen robust gegenüber EMV und ESD sein. imc bietet hierfür sowohl klassische HV-Thermo-Messmodule an, als auch innovative faseroptische Messmodule.

Thermoelemente auf 1400V Potential

imc CANSASflex-HISO-T-8-2L

- Isolation bis zu 1400 V (Gerätesicherheitsnorm EN 61010)

- 2 x LEMO.2P als Sammelstecker (4 Kanäle je 8-poligem Stecker)

- Kanalweise isolierte Messeingänge, individuelle ADCs, interne Vergleichsstellenkompensation

Thermoelemente auf 1000 V Potential

imc CANSASfit-HISO-T-8-2L

- 8 Thermoelementen (Typ-K)

- Sammelstecker

- HV-Gleichtaktniveaus bis 1000 V

PT100/PT1000-Sensoren auf 1000 V Potential

imc CANSASfit-HISO-UT-6-3L

- 6 x Spannung, PT100/PT1000, Widerstand, Beschleunigung

- Sammelstecker

- HV-Gleichtaktniveaus bis 1000 V

Spannungsmessung im HV-Umfeld

Ob Niederspannungssignale oder Spannungsmessung im Hochvoltkreis - bei Messungen im HV-Umfeld sind eine hochisolierte Messtechnik und entsprechende Sicherungsmaßnahmen notwendig. Auch bei Messungen an nicht direkt spannungsführenden Bauteilen wie etwa an Ladesteckern, Leistungshalbleitern usw. muss im Havariefall vollständige Sicherheit für Messausrüstung und Personal gewährleistet sein. Mit HV-Messmodulen und Hochvolt-Isolation im kV-Bereich ermöglicht imc sichere Messung an HV-Komponenten. Die Module entsprechen der Gerätesicherheitsnorm EN 61010 und verfügen über eine Isolation bis 1000 V CAT II.

Spannungen bis 100 V auf 800 V Potential

imc CANSASflex-HISO8-L

- 8 Spannungen, PT100/PT1000,

Widerstände, 20 mA - Einzelstecker LEMO.1P

- HV-Gleichtaktniveaus bis 800 V

- 1kHz Abtastrate

Strommessung

Ob zur Leistungsmessung, Verbrauchsmessung oder Untersuchung von Ladevorgängen: beim Testen von Hybrid- und Elektrofahrzeugen ist häufig eine hochgenaue Strommessung erforderlich. Mit imc CRONOSflex steht Ihnen eine umfassende Lösung zur Verfügung. Das modulare Konzept lässt sich auf verschiedenste Aufgabenstellung und Kanalzahlen anpassen. Isolierte Messverstärker für Messungen mit Stromzangen, Stromwandlern und Shunts sorgen für präzise Ergebnisse. Und über das Versorgungsmodul "CRFX/SEN-SUPPLY-4" können Fluxgate-Stromzangen und -wandler direkt aus dem Messsystem heraus versorgt werden. Das vereinfacht den Messaufbau gerade im mobilen Einsatz. Eine passend abgestimmte Auswahl an hochgenauen Stromwandlern speziell für e-Mobility-Tests bieten wir dazu an.

Leistungsmessung an elektrischen Fahrzeugen

Mit den HV-Messmodulen von imc können Spannung bis 1000 V direkt gemessen werden. Zusätzlich stehen Eingänge für Stromzangen, Rogowskispulen und auch für Messshunts zur Verfügung. Eine 1-, 2- oder 3-phasige Leistungsberechnung erfolgt online im Messsystem, inklusive Wirkleistung, Scheinleistung, Blindleistung und Leistungsfaktor.

Telemetrische mechanische Leistungsmessung

Die im realen Fahrbetrieb übertragene Leistung ist eine wichtige Kenngröße, um die Effizienz von Antrieben zu quantifizieren. Die Antriebsleistung ergibt sich aus Drehmoment und Drehzahl der Welle. imc bietet hierfür eine komfortable und robuste Messlösung: In ein leicht montierbares Wellengehäuse integriert das System Telemetrieelektronik, MEMS-basierte Drehzahlsensorik sowie induktive Energieversorgung. Aus Drehmoment und Drehzahl berechnet das System online die Leistung und gibt sie komfortabel als zusätzliche Messgröße aus.

Elektromotoren testen

Elektromotoren sind im modernen Fahrzeugbau allgegenwärtig. Neben Antriebskonzepten für Elektro- bzw. Hybridfahrzeuge spielen E-Motoren auch bei Sicherheitssystemen, Fahrerassistenz und Fahrzeugkomfort-Komponenten eine wichtige Rolle. Um bestmögliche Ergebnisse zu erzielen und höchste Qualität zu garantieren, ist in der Entwicklung und Serienfertigung eine umfassende Motordiagnose gefragt.

Hierbei realisierte imc bereits Prüfstände, mit denen der gesamte elektromotorische Antriebsstrang (Motor, Umrichter und Batterie) entwickelt und unter klimatischen Umgebungsbedingungen getestet wurde. Mehrere 100 kW Antriebsleistung und verschiedenste Prüfstandskomponenten werden mit imc MSR-Technik sicher und präzise gesteuert und geregelt.

Gemeinsam mit seinem Partner imx Solutions GmbH unterstützt imc Entwickler und Hersteller von Motoren seit über 30 Jahren mit Entwicklungs-, Komponenten-, Lebensdauer- und End-of-Line-Prüfständen.

Weitere Informationen zur Elektromotorenprüfung finden Sie bei unserem Partner imx Solutions GmbH

Elektrische Fahrzeugkomponenten auf Bordnetz-Konformität prüfen

Kraftfahrzeuge im Allgemeinen, wie auch Elektrofahrzeuge und Hybride im Speziellen, sind komplex vernetzte Systeme von Steuergeräten, Sensoren und Aktuatoren mit Energie- und Datenleitungen in Kilometerlänge. Das sichere Betreiben der Systeme erfordert umfangreiche Prüfungen aller möglichen Ereignisse, die im späteren Fahrzeugleben auftreten können. Sämtliche elektrische Komponenten müssen daher aufwändige Zertifizierungen durchlaufen. Als Mess- und Prüftechnik Spezialist ist imc Ihr zuverlässiger Partner, wenn es darum geht, Fahrzeugkomponenten nach internationalen Normen als auch nach herstellerspezifischen Prüfvorschriften zu bewerten.

Wichtige Normen wie z.B. die LV 124 bzw. LV 148 im 12V und 48V Bordnetz und die LV 123 im Hochvoltbordnetz, wie auch zahlreiche weitere, sind Standards, die imc sicher in Testumgebungen und Prüfständen beherrscht.

Mehr zur Prüfung elektrischer Fahrzeugkomponenten auf Bordnetz-Konformität

Weitbereichs-Strommessung

Moderne Hybrid- und Elektrofahrzeuge verfügen über ein aufwändiges Energiemanagement, um Energieflüsse im Fahrzeug zielgerichtet zu steuern. Neben dem Elektroantrieb gilt es Infotainmentsysteme, Aktuatoren und Steuergeräte zu versorgen - auch im ruhenden Fahrzeug. Daher ist es nicht zuletzt zur Reichweitenoptimierung wichtig, bei der Entwicklung von Fahrzeugen eine umfassende Energiebilanzierung im Bordnetz durchzuführen. In extrem weitgefächerten Messbereichen müssen dabei Ruhe- und Betriebsströme gemessen und analysiert werden, sowie Nachlaufenergie erfasst werden.

Das Messmodul imc CANSAS-IHR ist ein CAN-basierter Weitbereichs-Stromsensor der eine hochpräzise und unterbrechungsfreie Messung des Stromverlaufs von 50 nA bis 50 A erlaubt. Damit ist es möglich, z.B. Übergänge zwischen Ruhe- ("Sleep-Modus") und Betriebszuständen bei Automotive-Komponenten, Steuergeräten und Subsystemen lückenlos in einer kontinuierlichen Messung zu erfassen und zu analysieren. Verantwortlich für die hohe Bereichsdynamik (HR = High Resolution) sind dabei zwei unterschiedlich dimensionierte Messshunts, die in einem Auto-Ranging-Verfahren je nach Höhe des Stroms dynamisch umgeschaltet werden.

Wie klingt das Elektrofahrzeug der Zukunft?

Antriebsstränge und Nebenaggregate in Fahrzeugen mit Verbrennungsmotor werden seit Jahrzehnten hinsichtlich NVH (Noise, Vibration, Harshness) optimiert. Die Elektrifizierung ist hier eine große Herausforderung. Die fehlende Maskierung von Verbrennungsmotorgeräuschen offenbart neuartige Geräusche, mit denen sich Fahrzeugentwickler bisher nicht auseinandersetzen mussten. Die Beseitigung von Hintergrundgeräuschen oder störenden Schwingungen ist das Haupttätigkeitsfeld und wird auch weiterhin im Fokus der Akustikentwicklung stehen. Es ist auch wichtig, die gesetzlichen Anforderungen entsprechend zu erfüllen.

Neue akustisch relevante Phänomene von unterschiedlichen Elektromotorkonzepten bis hin zur Abbildung der Magnetostriktion und der Schwingungsproblematik elektronischer Bauteile wie Spulen oder Kondensatoren in der Leistungselektronik sind Themen der Akustikentwicklung.

High Performance Messräder für E-Fahrzeuge

Neue elektrische Fahrzeugkonzepte eröffnen durch die extreme Beschleunigungsfähigkeit des E-Antriebs bisher ungekannte Dynamik des Fahrverhaltens. Die dadurch gestiegenen Belastungen müssen natürlich im Entwicklungsprozess evaluiert werden, was ganz neue Herausforderungen an die Performance des dabei verwendeten Mess-Equipments stellt.

Die in diesem Bereich eingesetzten Messräder müssen erhöhte Kräfte und Momente erfassen können und nicht nur mechanisch, sondern auch gegenüber elektromagnetischen Störungen robust sein. Das umfangreiche Portfolio der telemetrischen Fahrdynamik-Sensorsysteme von imc ist genau dafür ausgelegt und prädestiniert.

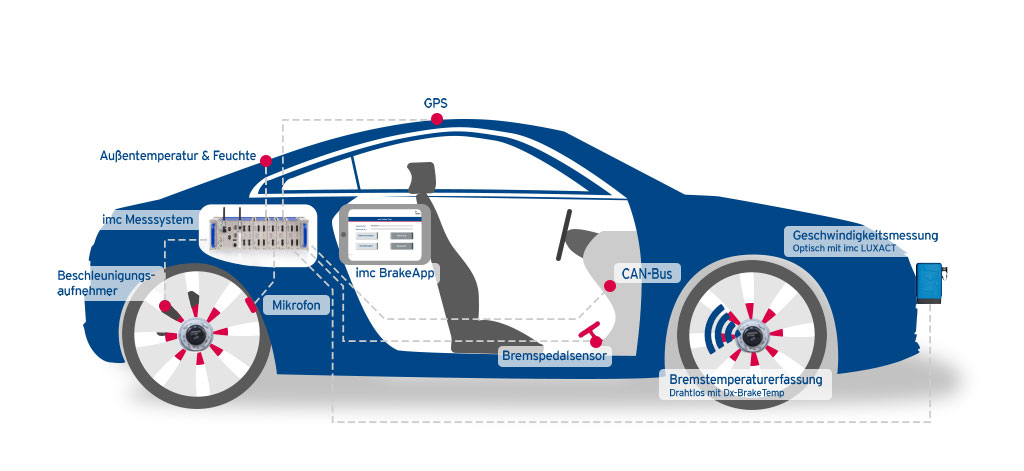

Messsystem für Radbremsentwicklung für E-Fahrzeuge

Durch die Rekuperation der Bremsenergie in Elektrofahrzeugen sind die Bremssysteme anders aufgebaut als in Autos mit Verbrennungsmotor. Ein Großteil der Bremsenergie wird zurück in die Antriebsbatterie gespeist. Deshalb kommen im Alltag die Radbremsen nur bei vergleichsweise starken Manövern oder als redundantes Sicherheitssystem zum Einsatz. Das imc Bremsmesssystem ist eine umfassende Testlösung und besteht aus einem modularen Datenerfassungssystem inklusive optionaler Sensorik und Radtelemetrie.