Dx-Power: Berührungslose mechanische Leistungsmessung an Fahrzeugen

Die im realen Fahrbetrieb übertragene Leistung ist eine wichtige Kenngröße, um die Effizienz von Antrieben zu quantifizieren. Die Antriebsleistung berechnet sich aus Drehmoment und Drehzahl der Welle.

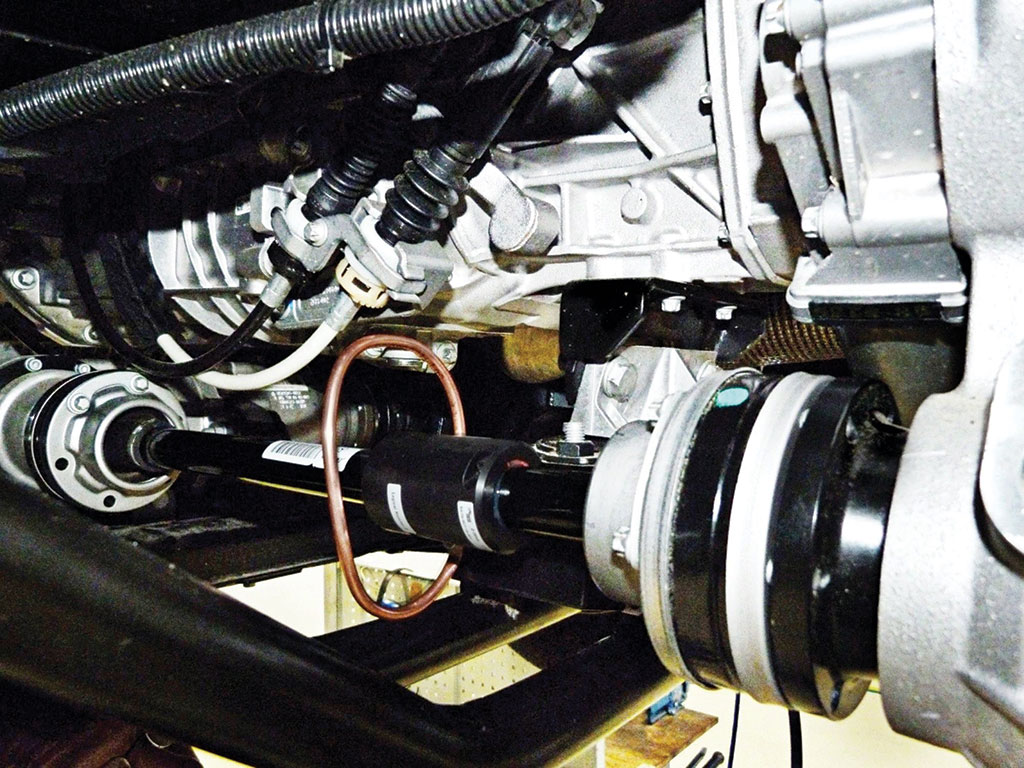

Das Dx-Power-System macht die mechanische Leistungsmessung an Achsen und Wellen zum Kinderspiel. Das System kommt ohne zusätzlichen Stator oder Referenzpunkt aus. Die Sensoreinheit (Dx-SCT) wird mittels eines Halbschalengehäuses direkt an die Fahrzeugachse montiert. Dort erfasst sie das Drehmoment (über DMS) sowie die Drehzahl über einen integrierten rpm-Sensor. Die gemessenen Daten werden telemetrisch an die Dx-Empfangseinheit (RCI) ins Fahrzeuginnere übertragen. Die Empfangseinheit berechnet die synchronen Werte der beiden Signale in Echtzeit nach der Formel Leistung = Drehmoment x Drehzahl und zeigt alle Werte in physikalischen Größen an.

Gewinner des messtec + sensor masters award

Auf der Veranstaltung messtec + sensor masters 2018 erzielte das Dx-Power-System den 1. Platz

in der Kategorie Sensorik. Dx-Power wurde ausgezeichnet als ein innovatives System zur berührungslosen Leistungsmessung an Fahrzeugen, das ohne zusätzliche mechanische Anbindung zur Drehwinkelerfassung auskommt.

Originalwelle bleibt erhalten

Die Dx-Power-Sensoren werden in Halbschalengehäuse verbaut, die individuell an den Wellen angebracht werden. Die Gehäuse gibt es in wasserdichter Ausführung und beinhalten alle nötigen Elemente:

- Dx-Power-Sensoren

- Dx-Sendeeinheit und

- Sekundärwicklung für die induktive Stromversorgung

Dank des flexiblen und leicht zu montierenden Gehäusekonzepts, kann die Originalwelle erhalten bleiben und muss weder gekürzt noch angepasst oder ersetzt werden. Die Rüstzeiten ist kurz und ermöglicht belastbarere Ergebnisse mit Serienbauteilen.

Bis zu vier Achsen synchron erfassen

Das Dx-Telemetriesystem kann mit bis zu vier Dx-Power-Sensoren zusammenarbeiten und somit die Messwerte von allen vier Antriebsrädern oder Kardanwellen synchron erfassen. Die Daten erscheinen in Echtzeit und können über CAN, Ethernet oder analog abgegriffen und weiterverarbeitet werden.

Technische Daten

| Dx-Power | |

|---|---|

| Maximale Drehzahl | ±7200 1/min |

| Genauigkeit | < 0,5 % bei 0 °C bis 50 °C |

| Signalfrequenz | 16 Hz (andere auf Anfrage) |

| Temperaturbereich | -20 °C bis +65 °C |

| Drehmomentmessung | DMS |

| Dx-Telemetrie-Sendeeinheit (SCT) | |

| Sendefrequenz | Dx: 13 Frequenzen im 868-MHz-Band Dx-HT: 17 Frequenzen im 2,4-GHz-Band |

| Abtastrate Summe | Max. 4,6/5,0 kHz pro Kanal (868-MHz-/2,4-GHz-Band) |

| Auflösung | 16 bit |

| Synchrone Messungen | Bis zu 4 Dx-Speed-Sensoren |

| Schutzart | IP 68 |

| Spannungsversorgung | Akku mit 40 h Betriebsdauer |

| Sendeleistung | Max. 10 dBm |

| Dx-Telemetrie-Empfangseinheit (RCI) | |

| Antenneneingänge | Zwei unabhängige Empfangssysteme im Diversity-Modus |

| Display | 2,83-Zoll-Farbdisplay, 320 x 240 px |

| Autozero | fernauslösbar |

| CAN-Schnittstelle | CAN 2.0b nach ISO 11898, max. 1 MBaud |

| Analogausgang | 6 BNC-Buchsen |

| Konfiguration | Bis zu 4 Dx-Speed |

| Spannungsversorgung | 9–36 Volt DC |

| Temperaturbereich | -20 °C bis +65 °C |

| Abmessung | Ca. 170 x 130 x 53 mm (ohne Antennen) |

| Gewicht | ca. 0,8 kg |