Integrierte Komponenten-Prüfstände

Prüfstände zum Test von elektromechanischen Komponenten: Effiziente integrierte Lösungen mit imc CRONOS und imc STUDIO

Integrated Component Test Stands

Test stands for electro-mechanical components: efficient and integrated solutions based on<link products measurement-hardware imc-cronoscompact overview internal-link internal link in current> imc CRONOScompact and <link products measurement-software imc-studio-software-for-measurement-control overview internal-link internal link in current>imc STUDIO.

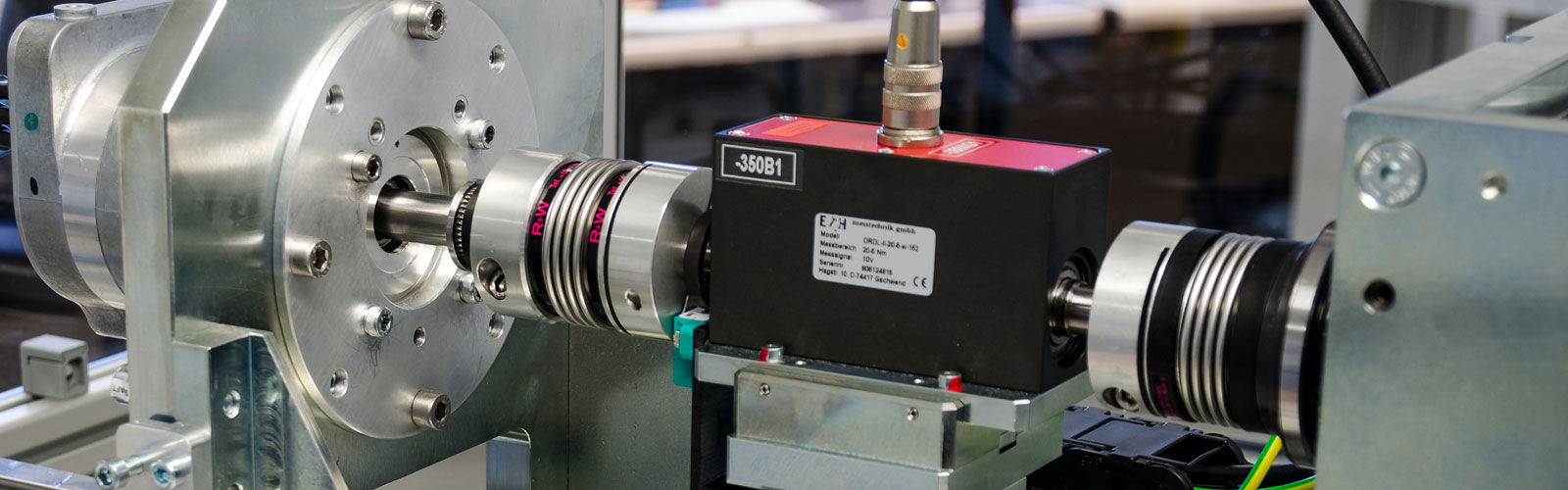

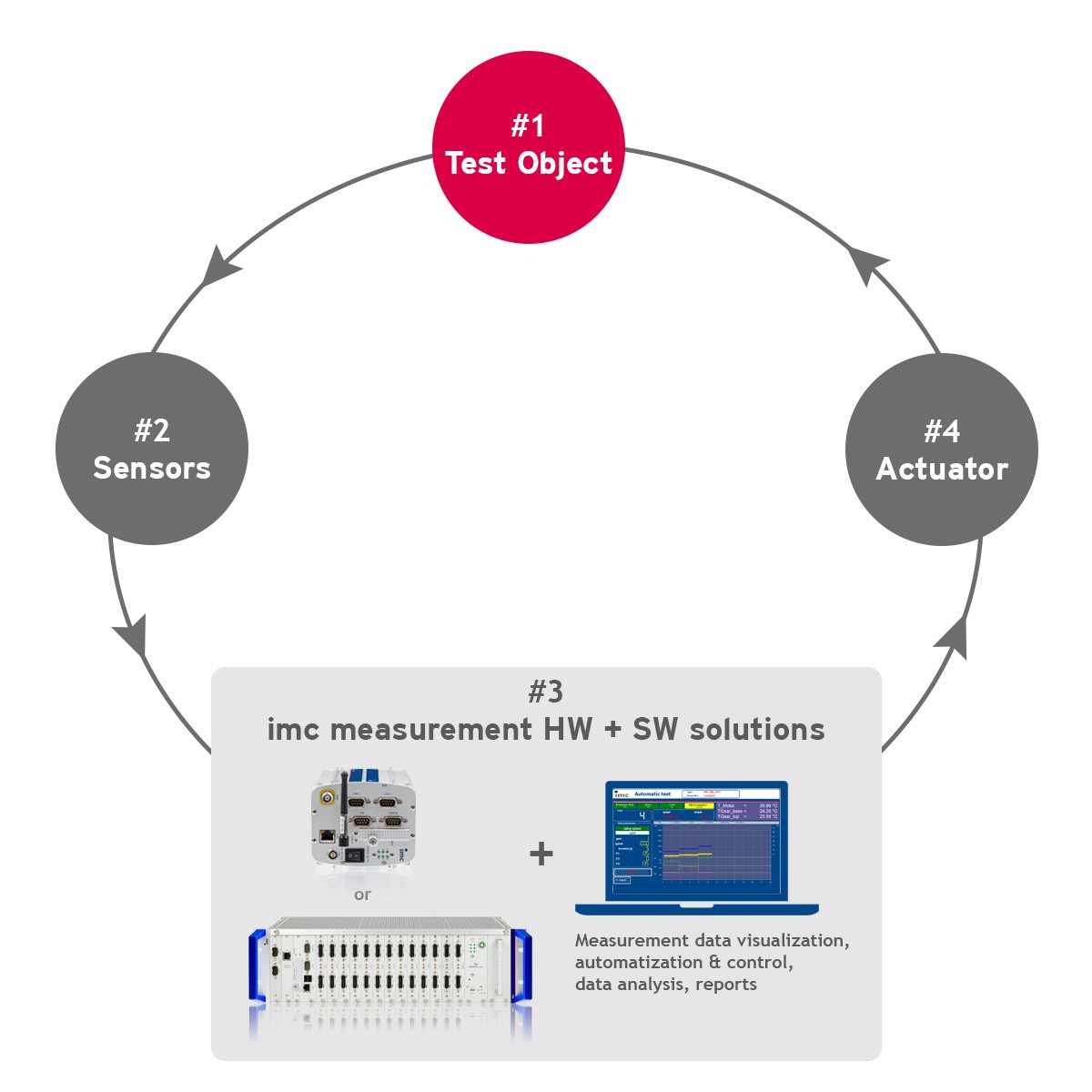

Systematic test of electro-mechanical components and products is an important task that product engineers have to face in development departments, with longterm endurance testing, or in end-of-line mass production scenarios. What is needed in these cases, are component test stands that are capable to quickly and easily adapt to changing test requirements.

To find efficient and cost-effective solutions, the entire life cycle of a test stand has to be considered. From rapid implementation to trouble free operation that ensures high throughput to easy maintainability. Adaptations and extensions should be supported fast and easliy - and if possible without the need to involve extensive pre-gramming by software development or ecen external service providers.

To meet these manifold requirements, an integrated solution his highly preferred, based on flexible components in terms of hardware and software. imc CRONOS and imc STUDIO offer a perfect solution for this task. They allow to easily realize test stand applications of various scales for components not only for automotive, but from any possible field and industry.

The full white paper is available as a PDF in the column on the right under "Downloads".