Elektrische Fahrzeugkomponenten auf Bordnetz-Konformität prüfen

Die Elektromobilität konfrontiert Fahrzeughersteller wie auch Zulieferer von elektronischen und mechatronischen Kfz-Baugruppen mit einer stark gestiegenen Komplexität beim Zusammenspiel der Elektronikkomponenten und Bordnetze und dadurch mit hohen Qualitätsanforderungen. Das Erfüllen internationaler Normen und herstellerspezifischer Prüfvorschriften wie z.B. in der LV 124 beschriebenen Tests, sind ein elementarer Bestandteil für die Entwicklung neuer Fahrzeugkomponenten. Diese werden dabei vordefinierten Signalverläufen des Bordnetzes ausgesetzt.

In Kooperation mit der Firma BOLAB Systems bietet imc Lösungen für die Überprüfung der Bordnetz-Konformität nach LV 124, LV 123 und viele weitere an. BOLAB Systems ist Spezialist für Testsignalgeber und 4-Quadranten Spannungsverstärker.

Der LV-Prüfautomat

imc bietet schlüsselfertige, vollautomatische elektrische Prüfstands-Lösungen für verschiedenste KFZ-Komponenten nach unterschiedlichsten Prüfnormen.

Die Vielzahl der umgesetzten Prüfnormen wurde dabei von Vertretern führender Kfz-Hersteller wie Audi, BMW, Volkswagen, Porsche und vielen weiteren namenhaften Herstellern zusammengestellt und um deren herstellerspezifische Testvorschriften erweitert.

Die imc Entwicklungsprüfstände für Klimakompressoren können neben den LV-Norm-Messungen auch entwicklungsbegleitende Motorprüfungen durchführen, wie z.B. Back-EMF oder Kennlinienmessungen. Alle Prüfungen sind komplett integriert und werden mit imc STUDIO durchgeführt.

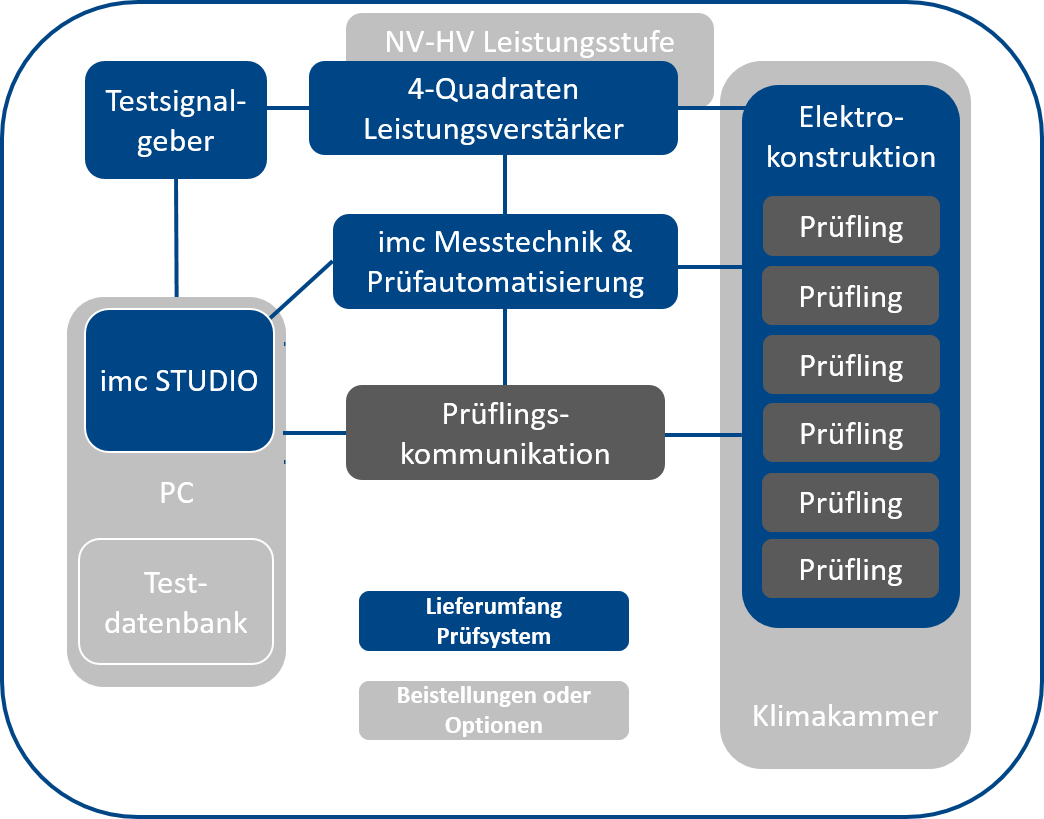

Systemtopologie der imc Prüfstandslösung

imc bietet schlüsselfertige Prüfautomaten zum Steuern der Prüfabläufe bzw. Prüfnormen. Das imc System bietet einen modularen Aufbau, Erweiterungsmöglichkeiten und den flexiblen Einsatz von verschiedenen Leistungsendstufen und Messtechnik. Vollautomatische Prüfabläufe auf Basis von Teilprüfungen mit flexiblen Prüfparametern steigern Ihre Produktivität und vermeiden Fehlbedienungen. Die direkte Ergebnisbildung (Prüfprotokoll) und eine strukturierte Datenablage erleichtern die Arbeit mit dem System. Die Auswertungen werden am Ende der Prüfung direkt zur Weitergabe an den Endkunden zur Verfügung gestellt.

Vorteile des imc Systems

- Prüfen von mehreren Prüflingen ohne aufwendigen Umbau

- LV124 / LV148 / LV123 mit einer einheitlichen System-Architektur

- hohe Kostenersparnis - Schnelle und präzise Anstiegs- / Abfallzeiten (ca. 1,5µs)

- Durchgänge Kalibrierung und Rückverfolgbarkeit auf Systembasis

- Modularer Aufbau erlaubt Integration beliebiger Leistungsquellen

- Kostenersparnis und Flexibilität bei Einsatz vorhandener Komponenten, z.B. Leistungsnetzteil

Individuelle Systemgestaltung

- Realisierung und Funktionalitäten nach Kundenwunsch

- Prüfeinrichtung mit CE Norm und ggf. Sicherheitskonzept

- Kundenspezifische Anschlusstechnik der Prüflinge

- Flexible und modulare Elektrokonstruktion

- Integration von vorhandenen Leistungskomponenten

- Ergebnisdatenbank (optional)

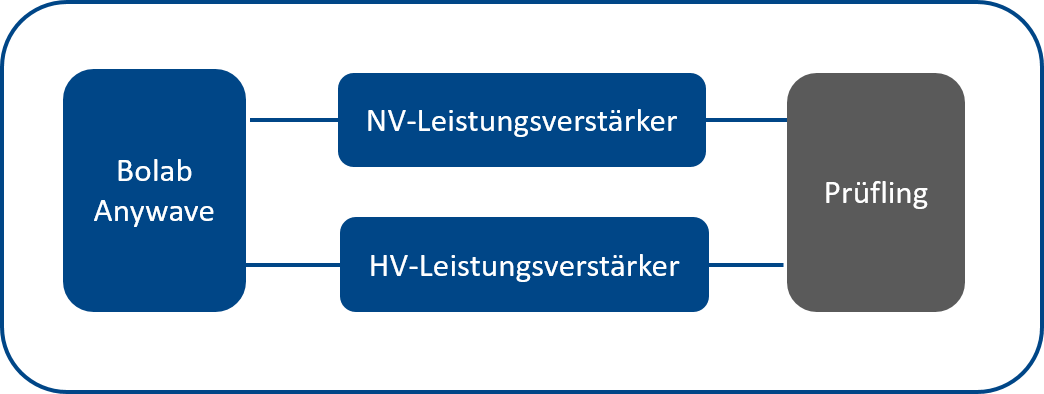

Die BOLAB AnyWave-Steuereinheit bedient alle Arten von Netzteilen sowie 4-Quadrantenverstärker über die analogen Schnittstellen. Sie verfügt über zwei analoge Ausgänge, um zwei Wellenformen synchron bereitzustellen an verschiedene Netzteile bzw. den 4-Quadrantenverstärker. Dank internem Speicher können Signalprofile nahezu unendlicher Länge simuliert werden. Dies bietet den größten Vorteil im Vergleich zu Funktionsgenerator-Lösungen, deren Speicher und Geschwindigkeit aufgrund ihrer Funktion begrenzt sind.

Die BOLAB Leistungsverstärker sind modulare, kaskadierbare 4-Quadranten Verstärkersysteme. So erlaubt das Systemkonzept die Prüfung der Bordnetzseite und der HV-Seite in einer Lösung.

Die Netzteil- bzw. 4-Quadrantenverstärker-Systeme sind zwischen 500 W und 18 kW mit folgenden Eigenschaften kaskadierbar:

- DC - 200 kHz Bandbreite (Kleinsignal-Bandbreite bis zu MHz)

- Ausgangsspannung ± 100 Vpk

- Anstiegs- / Abfallzeit 100 V / µs

- USB-Schnittstelle

- analoger Steuereingang ± 10 V zur Steuerung von Spannung und Strom.

- Modular erweiterbar über Master-Slave-Modus

- Parallel- und Reihenschaltung für zwei oder mehr Geräte

Wir unterstützen grundsätzlich herstellerunabhängig alle Netzteile und integrieren die gewünschten Leistungskomponenten in Ihre Lösung. Voraussetzung ist die analoge Ansteuerbarkeit. Mit zahlreichen Netzteilen der Firmen Delta, Regatron, Heinzinger, EA etc. haben wir bereits Aufbauten realisiert.

imc bietet die passende Messtechnik für alle elektrischen und physikalischen Größen von HV bis zum Brückenmessverstärker an.

- Messbereiche 5 mV bis 1000 V

- Bis 4 MHz pro Kanal und 24 bit Digitalisierung

- Höchste Präzision durch individuell isolierte, gefilterte und digitalsierte Messkanäle

- Faseroptische Messtechnologie für Prüflinge im HV-Bereich (Personenschutz und störungsfrei messen)

- Schnittstellen für Steuergeräte (CAN/CAN-FD/LIN/FLEX-RAY/XCPoC & XCPoEtherNet)

- Restbussimulation auf dem System

imc STUDIO Software

Die Steuerung und Bedienung des Gesamtsystems übernimmt imc STUDIO. Eine Software für Datenerfassung, Visualisierung, Automatisierung, Prüfstandssteuerung und Regelung.

Ihre Vorteile auf einen Blick:

- Metadaten – Manuelle Eingabe, automatisiertes Einlesen eines Excel Sheets oder kundenspezifische DB-Schnittstelle versuchsbeschreibender Daten

- Steueroberfläche – Allgemeine Konfiguration der Geräte (z.B. Messkanäle …), Einstellung der Datenablage, …

- Handbetrieb - Einrichten und manuelle Einzelprüfung

- Automatikbetrieb – Automatisierter Ablauf von Einzelprüfungen mit Prüfprotokollen und strukturierter Datenablage aller relevanter Prüfdaten

- Prüfablaufeditor – Tabellarische Konfiguration eines automatisierten Prüfablaufs, bestehend aus Teilprüfaufgaben bzw. Prüfschritten

- Datenvisualisierung – Darstellung der Prüfgeber-Daten sowie der dazugehörigen Prüfschritte und Messdaten.

- Auswertepanels – Visualisierung der Prüfergebnisse als automatisierter „Plot“ der jeweiligen Teilprüfung