Rugged data acquisition (DAQ) system for harsh environments

No more compromises: With the imc CRONOS-XT, imc is offering for the first time an ultra-robust device in a completely modular platform. The rugged data acquisition base unit and a number of amplifiers can be conveniently connected to form a complete system: without tools and cables via a simple click-mechanism. With protection class IP67 and MIL-STD810F, the system is protected against dirt, dust and water as well as severe shocks and vibrations. The rugged data logger is therefore ideal for mobile measurements on construction machinery, tractors, agricultural machinery and vehicle testing that takes place in harsh environments.

Perfect for mobile use in harsh environments

-40° bis +85°C

Operating, condensation allowed

distributable

distributed blocks via EtherCAT

MIL-STD-810F

Particularly resistant to shock and vibration

GPS

Synchronous position and geo data

IP67

Water- and dustproof

10 - 35 VDC

Wide input voltage range

More flexibility for everyday testing

Is an 8-channel vibration measurement planned for today? Then simply click the ICP module on your base unit and off you go. And tomorrow? Thanks to the modular building block technology, the DAQ system can be ideally adapted to the measurement task at hand. A broad selection of high-precision universal and special measurement amplifiers allow the direct connection of almost all sensor types, such as thermocouples, RTD (PT100/1000), voltage and current signals, acceleration and sound sensors (IEPE), displacement transducers (LVDT), all the way to strain gauges as full/half/quarter bridges and corresponding bridge sensors such as load cells. The precise and low-noise measurement amplifiers digitize with 24 bits and have high bandwidth and range dynamics.

Extremely robust DAQ system

- Water- and dustproof according to IP67

- High shock and vibration resistance according to MIL-STD-810F

- Robust, impact-resistant housing

- Sealed electronics (condensation-proof)

- Wide temperature range from -40 °C to +85 °C

System design

Spatially distributable

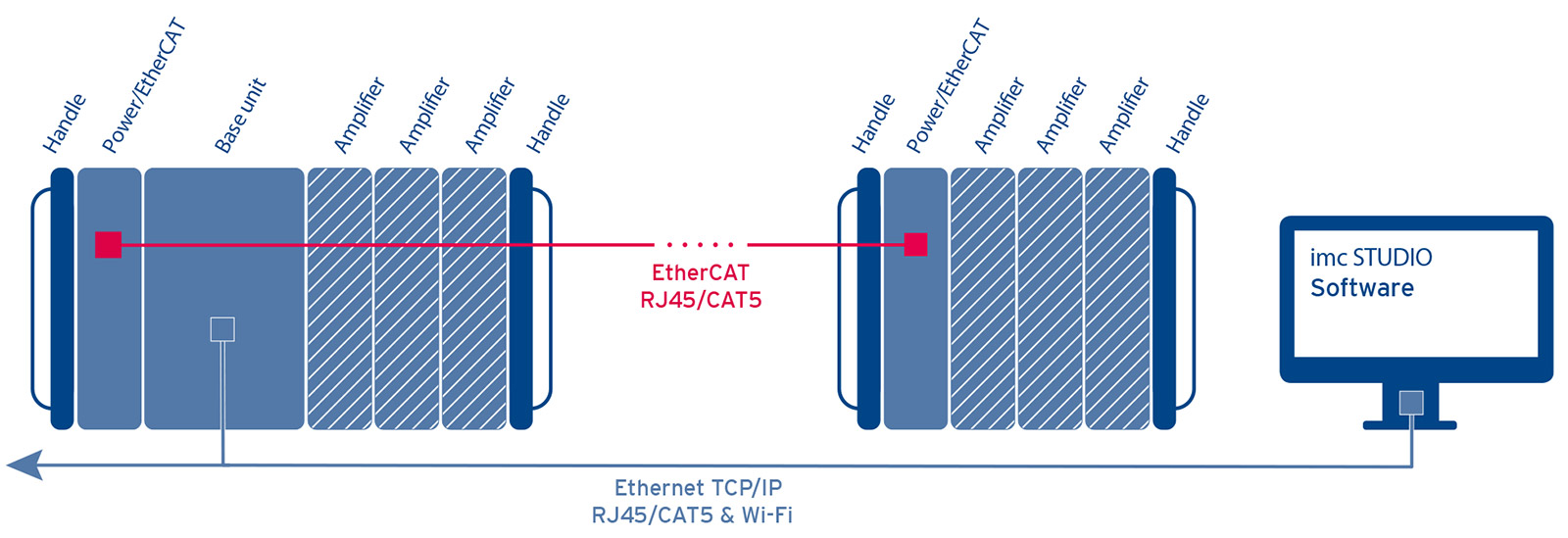

In addition to the modular design as a centralized system, imc CRONOS-XT can also be installed in a spatially distributed topology. This allows measurement amplifiers to be placed close to the sensor in order to keep the length of sensitive and expensive cables to a minimum. Networking is accomplished via the EtherCAT-based imc system bus. All data converge synchronously in the base unit.

Networkable with multiple devices

For extensive measurements with hundreds or thousands of channels, multiple imc CRONOS-XT, as well as all other imc measurement devices, can be operated together as a single system. The devices are networked via Ethernet and synchronized via DCF77, IRIG-B, GPS or PTP. The data are stored autonomously in the devices and/or transferred to a NAS or PC via network streaming.

Real-time analyses in the device

Be sure to get finished results while the measurement is still running. With the integrated imc Online FAMOS computing platform, you can calculate and analyze your raw data in real time. Using a convenient assistant, you can create your own personal real-time analyzer: simply drag & drop from a comprehensive collection of mathematical and static functions as well as finished analyses such as FTT, class counting and order tracking. This makes it possible to create your own evaluation algorithms and set up smart data analyses without programming.

Compressed and intuitive results are not only available directly from the stand-alone device (without PC), they can also be displayed live on an imc handheld display. During the test, e.g., during a test drive, you get immediate feedback on the running test, which can then be reacted to immediately, e.g., by appropriate driving actions.

In practice

Testing under harsh conditions

The stress that is imposed on machines for construction and agriculture can be enormous. This makes it all the more important to carry out comprehensive functional and stress tests when developing such machinery. imc CRONOS-XT provides test and measurement engineers with the perfect tool for such tasks. Universal measurement amplifiers precisely measure all sensors installed on the machine including strain gauges, IEPE/ICP, displacement, force and pressure and perform real-time analyses, e.g., for rosette calculations or spectral analysis (FFT). The robust housing reliably protects the equipment from dust, dirt, water and mud.

Keeping track of noise and vibration

To protect both people and the environment from noise, vehicles and machinery must comply with many regulations. These not only include noise emissions, but also vibrations affecting people and components. With imc CRONOS-XT in conjunction with imc WAVE software, users have a complete package for noise and vibration analyses at their disposal: From noise measurements during road tests through structural analyses on the test bench to vibration tests in the field.

Fatigue testing and load profiles

The imc CRONOS-XT provides test engineers with the ideal system for acquiring real live road load data and operate fleet monitoring. Thanks to the high shock and vibration resistance according to MIL-STD-810F, imc CRONOS-XT is able to reliably record test data even under extreme conditions. Functions such as self-start, online class-counting, GPS tracking and cloud connection for measurement data transfer and online monitoring are particularly helpful for week-long test drives.

Comfortable measurement software

No matter whether you want to configure your imc CRONOS-XT for a fast mobile measurement in “black box” mode, set up live monitoring for hundreds of channels for prototype testing or create a complete test bench automation with your own control panel – with imc STUDIO you have full control over your complete measurement process: from channel configuration to report. imc STUDIO combines data acquisition, visualization, analysis and automation.