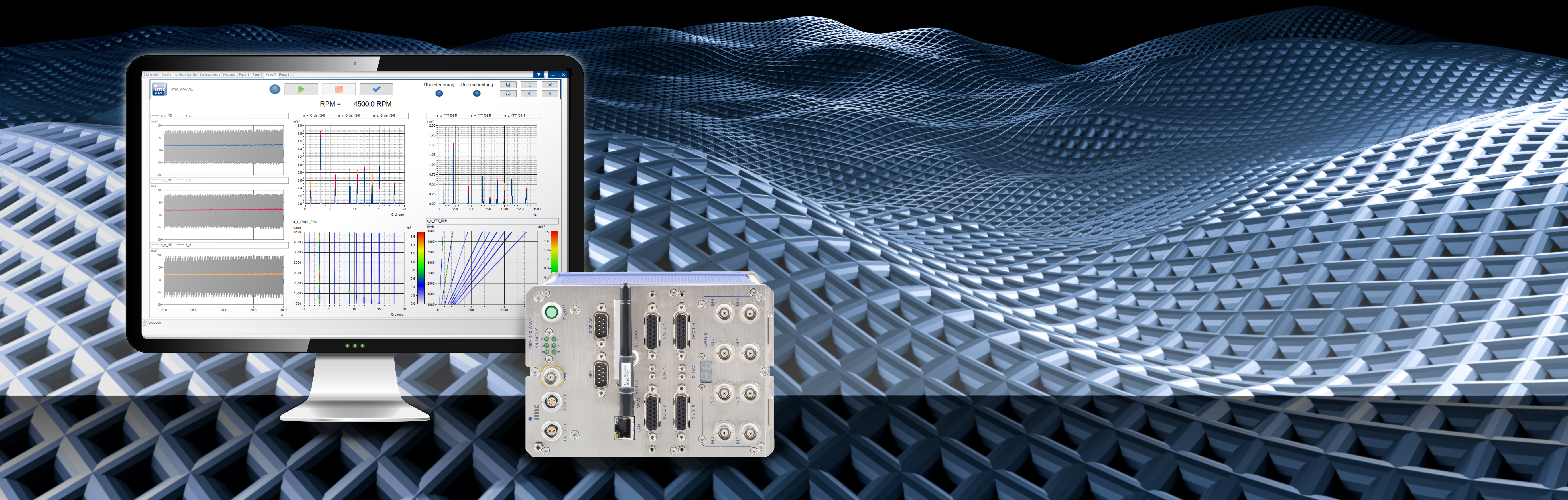

Online Ergebnisse

- Messmodule zur hochgenauen (zeitliche Auflösung von 256 MHz)

- Erfassung von Zeit- oder Frequenzinformationen mittels digitaler Zähler.

- Drehzahlberechnung aus Sinus und Puls Signalen

- Umdrehungsabhängiges synchrones Nachabtasten (Resampling)

- Ordnungsspektrum als 3D über der Umdrehungen oder der Drehzahl

- Klassierung und Darstellung der Ordnungsspektrum über der Drehzahl oder einer anderen Messgröße

- FFT-Spektrum über der Zeit, der Drehzahl oder einer anderen Messgröße

- Darstellen einzelner Ordnungen

Typische Anwendungen

- Messungen und Analyse während des Hoch- und Auslaufs rotierender Maschinen.

- Messungen und Analyse bei konstanten Drehzahlen zur Überwachung von vielfachen Produktqualifizierungen

- Produktoptimierungen im Entwicklungsbereich

- Qualitätssicherung für End-Of-Line

- Ganzheitliche Untersuchungen zu Ursachen, Ausbreitungswegen und Auswirkungen an drehenden Maschinen mit beliebigen physikalischen Messgrößen wie (Schall, Beschleunigung, Geschwindigkeit, Weg, Drehmoment, Torsion über Pulse, Kräfte, Drücke, Temperaturen digitale Bus-Daten z.B. CAN-Bus u.v.m.

Wie entstehen Schwingungen an Maschinen?

Schwingungen entstehen durch hin und her-Bewegungen von bewegenden bzw. drehenden Maschinen. Beispielsweise: Kolben, Kompressoren, Rotoren, Wellen und Walzen, sowie Getriebe und Pumpen. Die Amplitude und die Frequenzen ist abhängig von den Eigenfrequenzen und Steifheit Zusätzliche Stöße durch Schäden einzelner Bauteile werden Maschinen zusätzlich breitbandig angeregt und anhand der Amplituden und der Frequenzen können Maschinen- und Bauteilfehler erkannt und lokalisiert werden. Beispielweise: Unwucht, Wälzlagerschäden oder Ausrichtfehler.

Welche Sensoren werden für eine Messung benötigt?

- Drehzahl-Sensoren

- Drehzahl-Sensor mit Puls-Ausgabe z.B. 360 Pulse pro Umdrehung, zum Anschluss an einen imc Inkremental-Geber Eingang (Zähler)

- Drehzahl-Sensor gibt proportionale Spannung oder Strom (4…20 mA) aus, zum Anschluss an einen analogen Eingang.

- IEPE Sensoren für Beschleunigung, Schwing-Geschwindigkeit, Wegsensoren, Mikrofone, Kräfte, Drücke.

- Alle Sensoren müssen zeitsynchronisiert erfasst und können dann im Online imc WAVE verrechnet und dargestellt werden.